What Is a Centrifugal Pump ?

Centrifugal pump are used to move liquid by the conversion of rotating kinetic energy to the hydrodynamic of the liquid flow. The rotating energy commonly comes from a electric motor. The liquid enters the pump impeller along the rotating axis and is accelerated by the impeller.

Common uses of a Centrifugal Pump are for water, sewage, agriculture, petroleum and petrochemical pumping. Centrifugal pumps are chosen for their high flow rate, abrasive solution, mixing, as well as their relatively simple engineering.

How Does a Centrifugal Pump Work ?

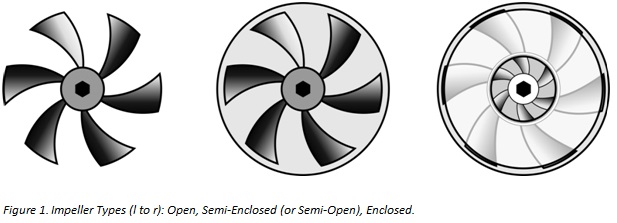

The impeller is one of the most important component of a centrifugal pump. It consists of a series of curved vanes. The vanes are normally in between two discs ( enclosed impeller ). For fluids with solids, an open or semi-open impeller is preferred.

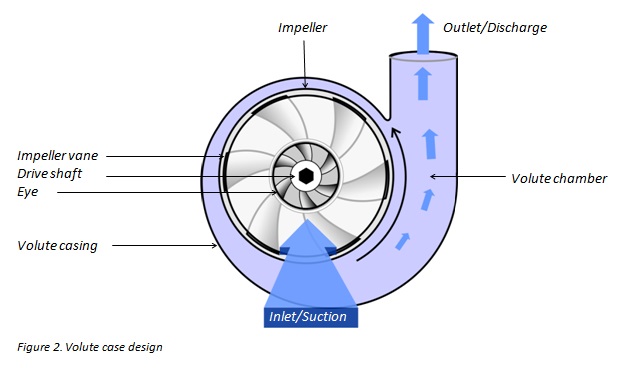

Liquid enters the impeller at the center axis and exits along the circumference between the vanes. The impeller, on the opposite side is connected through a drive shaft on a motor and rotating at a high speed. The motion of the impeller accelerates the liquid out through the impeller vanes into the pump casing.

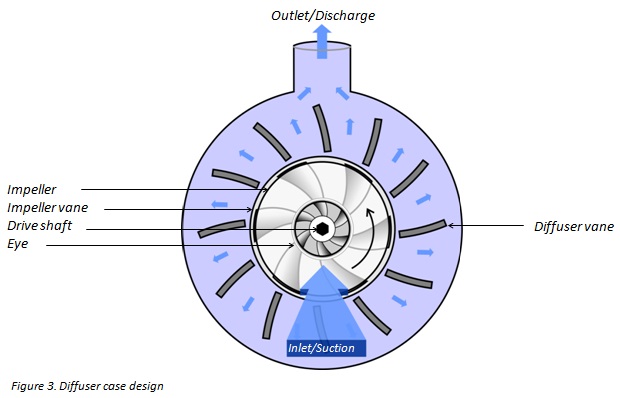

There are two basic designs of a centrifugal pump casing: volute and diffuser. The purpose in both designs is to control discharge at a specific pressure.

The volute casing impeller is offset, effectively creating a funnel with an increasing cross-sectional area towards the pump outlet. This design causes the liquid pressure to increase towards the outlet .

The Diffuser design Shares the same principle. The fluid pressure increases as the liquid is expelled between a set of stationary vanes surrounding the impeller. This designs can be customize for a specific applications, therefore it could be more efficient. Volute cases are better suited for solids or high viscosity fluids when it is advantageous to avoid the added constrictions of the diffuser's vanes. The asymmetry of the volute design can cause greater wear on the impeller and drive shaft.

Images Credit : Michael Smith Engineers